CREATED BY NATURE.

INVENTED FOR THE SAKE OF NATURE.

Currently used outdated precious metal extraction technologies are inefficient or highly toxic. This is the reason for frequent ecological catastrophes of global consequences. The scale of this problem illustrates the amount of cyanide waste (about 20 tons) created in the process of gold mining to produce only one

pair of wedding rings!

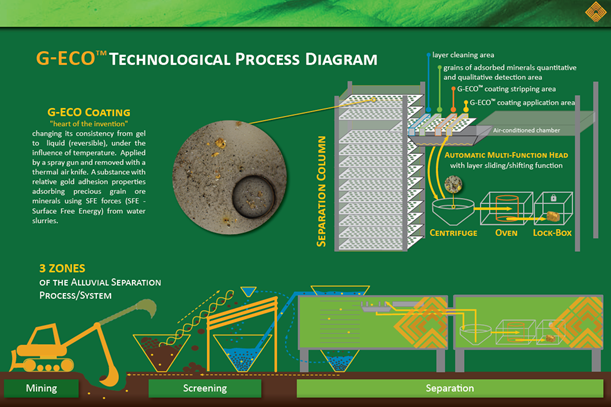

G-ECO method utilizes the phenomenon of adhesion (Latin adhaesio – adherence) to separate metallic gold from ores. It’s a process of matching materials of specified surface free energy (SFE). The phenomenon of adhesion in nature can be observed with the example of droplets of hanging water on a several hundred times thinner spider’s web or a few centimeters small gecko walking on the ceiling & being able to hold a weight of up to 30 kg! The essence of G-ECO and the patent claims of this invention is the method of matching the parameters of the SFE of G-ECO to the parameters of the SFE of GOLD. As a result of the proper matching of these two parameters, the selectivity and adhesion power of the selected minerals to

the G-ECO coating is the result. G-ECO material is based on the latest nano adhesive

knowledge and apart from gold also selectively chooses platinum, palladium, rhodium, other noble metals and microdiamonds. In G-ECOTM separation systems, particles from 1 μm to 2 mm are recovered and the efficiency of the separators is over 95%. A separator with the size of 25x25x200 cm has a processing capacity of about 20 tons of ore per hour. Only water is used in the separation process and G-ECOTM is highly resistant to solid erosion, which does not release any harmful substances into the environment.

Clean

Economic

Effective

G-ECO AREAS OF USE

DUMPS & TAILINGS

Estimated cost of recovery using the

G-ECOTM method of the smallest fractions lost

by gravity installations is about $ 150 / ounce

(cost estimation for a sandy earth/ore deposit

of about 2 g gold per ton)

- General admission and member discounts for one adult

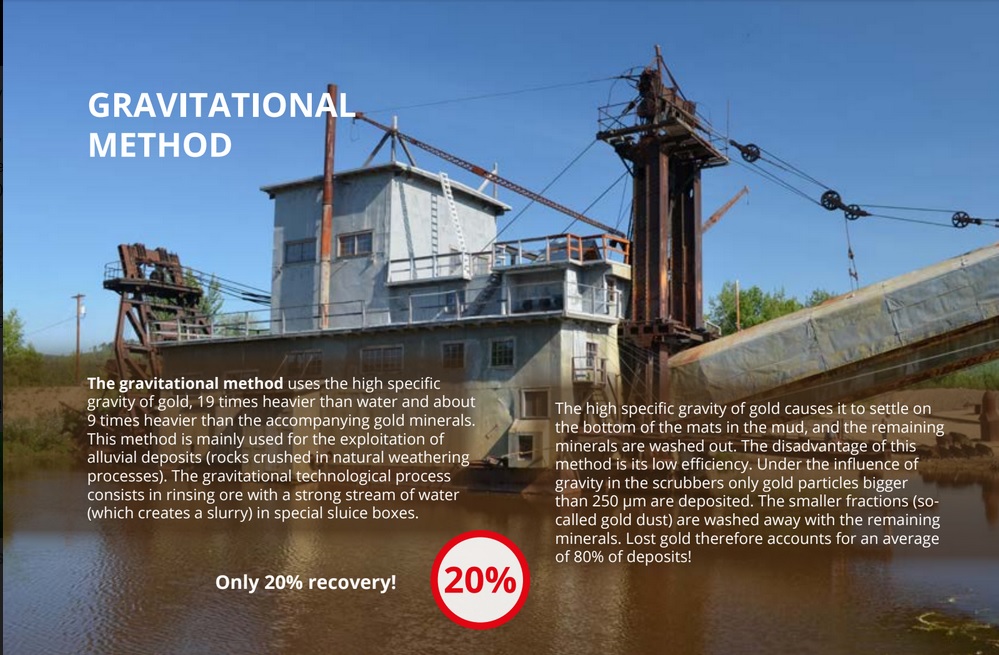

GRAVITATIONAL INSTALLATIONS

the use of G-ECO separation units in existing gravity installations will increase gold production by approximately 400% (recovered

fractions below 250 microns represent 80% of

average deposits)

- General admission and member discounts for two adults

PRIMARY DEPOSITS

The mining costs of gold-bearing rock

remain unchanged, the cost of rock crushing decreases slightly, but the cost of separation drops from about $ 225 USD ounce in the cyanide method to about $ 45 USD ounce in the G-ECO method. CAPEX investment costs for G-ECO installations in relation to cyanide installations are several hundred times lower. The G-ECOTM method also eliminates the long-term costs of the disposal of toxic waste.

- General admission and member discounts for two adults